Authored by Robert Nimmo

Robert is the ArborGen Bluff City Nursery Manager.

How close together your seedlings are planted will determine just what financial return you achieve.

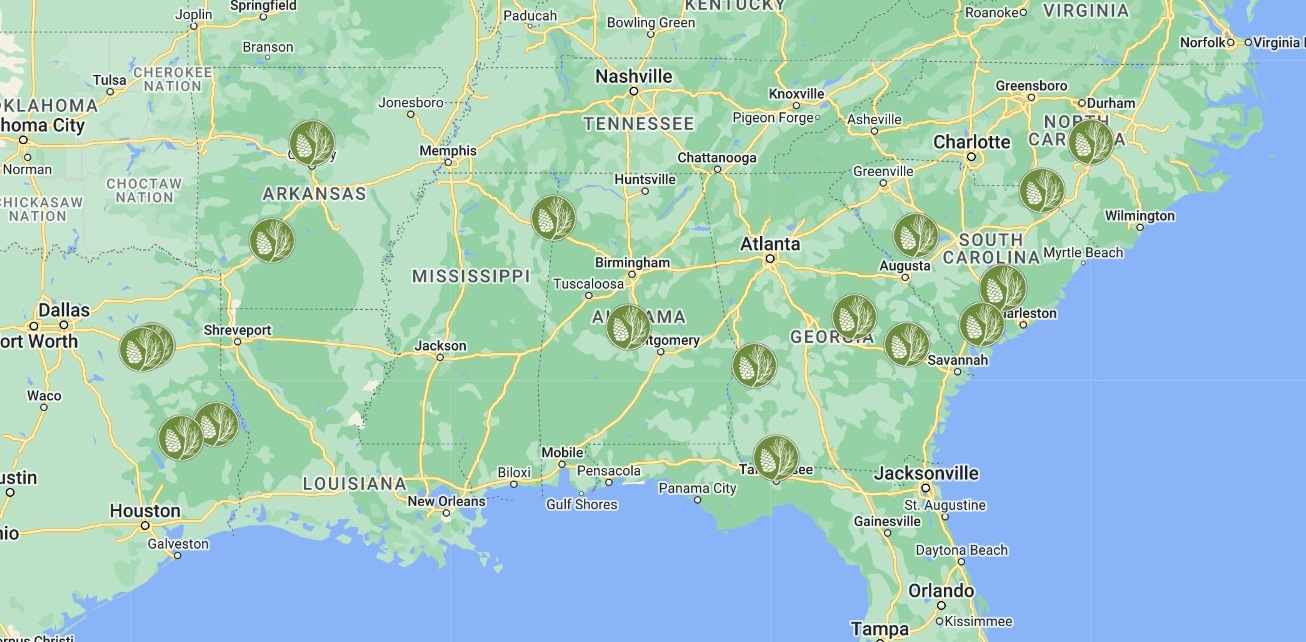

Among the many essential decisions necessary when establishing loblolly pine plantations, one of the most important ones is “what tree spacing should I use?” Landowners must be fully aware of the options and their implications, as they will have to live with those front-end decisions for the next 25 – 35 years. We are aware of many landowners who are not getting good advice concerning this important issue and will suffer financially as a result.

10 x 10 spacing at age 10. 435 trees per acre.

Key factors to consider are what markets are your growing timber for, what type of genetics are you planting, are you planting bare root or container seedlings and is the property steep, making thinning unlikely….and what is the minimum width between rows that the logging equipment needs to operate in a thinning. In some cases, the tree spacing being used can actually prevent the effective use of the harvesting equipment used for thinning- a critical factor in determining the ultimate value in the residual stand and a key determinant of the landowner’s profitability.

Some tree spacings create severe limitations to your forest management activities and, most importantly, what you will be able to harvest. With the financial investment and time spent on establishing your new plantation, the last thing you want is to have unknowingly created limitations on your financial return by using the wrong tree spacing. The tree spacing selected at the establishment will heavily determine the first thinning method and subsequent harvest. And this first thinning can often be a “make or break” activity for the future value of your plantation. Remember too, that planting advanced genetics like MCP® yields trees with better straightness and lower defects so that you do not have to plant as many trees to get a high volume of sawtimber in your post-thinning, residual stand.

8′ x 10′ spacing, or 545 trees per acre.

Consider an example property with roadside access, which is well-drained, facilitating wet weather logging. These are ideal timber tracts as they give the landowner optimum flexibility for logging and thus attract more buyers in times of high wood demand when inventories at mills are more constrained. In this scenario, the spacing chosen by the landowner becomes critical if they sell the first thinning during wet weather conditions for more advantageous pricing. Cutting machines and skidders are often at least 10-12’ wide during dry weather, but during wet conditions, larger tires are added for better performance in the more challenging conditions. The larger tires can stretch the width of the machinery to 14 or even 18’. Frequently, 1st thinnings are set up to take out every 4th or 5th row, with residual rows selectively harvested to leave “crop” (the best) trees for the subsequent thinning or final harvest, i.e., chip-n-saw and sawtimber.

If a landowner were to plant on 10’ wide rows, the wider equipment barely has enough room to operate after removing the “take-out” row. Rows on 8’ widths (8 x 8) would pose even more issues, with two rows possibly needing to be removed for operability. We have seen, and customers have told us, this is being done. This will cost you money!

First, too much volume has to be removed, as much as 50% of the stand to provide operability leaving a lower number of crop trees and yielding a substantial amount of pulpwood, which may be difficult to market. Second, even if the logger practiced the utmost care, fell-bunchers and skidders operating in such tight conditions would ultimately damage residual trees…your future sawtimber crop trees! Again, the tighter the row and within-row spacing, the more trees must be sacrificed for mechanical operability.

This non-selective elimination of trees defeats the overall purpose of leaving more choices for crop trees evenly spaced across the tract. The goal of the first thinning is to remove as much poor quality/pulpwood stems as possible while at the same time leaving as many good quality, evenly spaced stems in the residual stand to become solid wood products.

Most landowners want to establish forest plantations with maximum flexibility and options for future wood markets. Now that we understand how the size of modern-day harvesting equipment affects row spacing, landowners have the chance to establish plantations with built-in measures for success.

21st century silvicultural and genetic innovations easily give landowners the option to extend planting row widths out to 12 or even 14’. Some have even chosen to try 16 and 18’ row widths for modern-day genetic options. Many spacing options for consideration present a wide range of options.

Your ArborGen Reforestation Advisor can provide additional information on recommended tree spacing for seedling type and level of genetics.