Authored by Blake Sherry

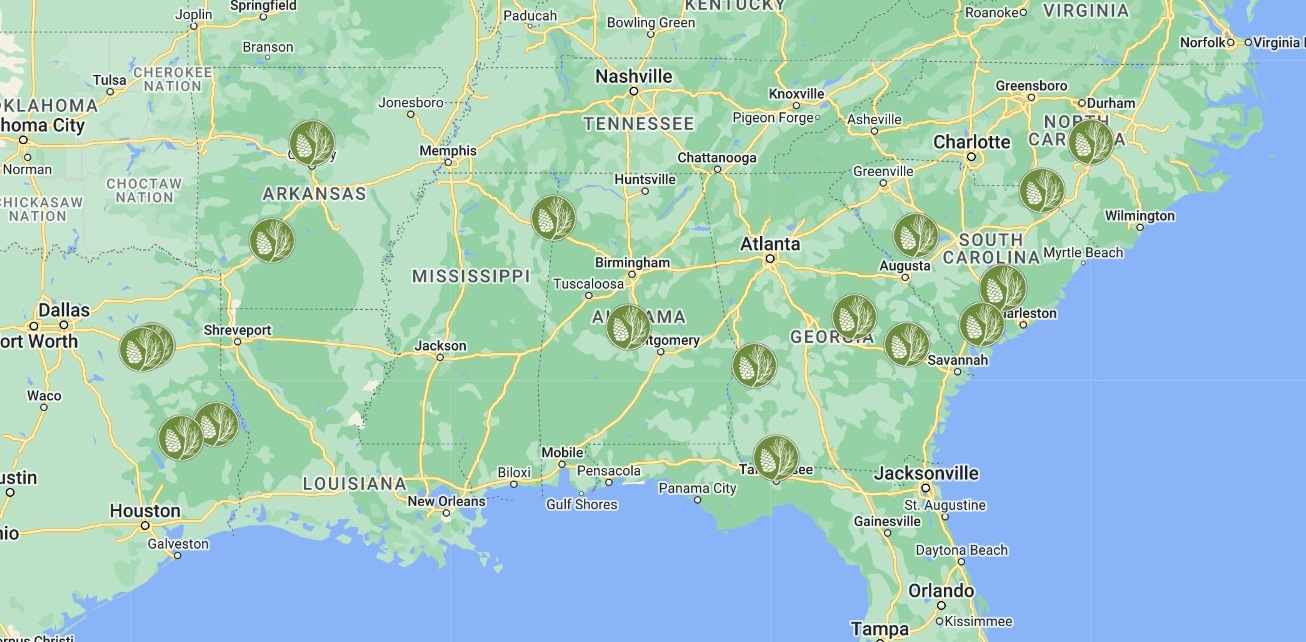

Blake Sherry is the Reforestation Advisor for Florida, Southern Georgia, and Southern Alabama.

Blake joined ArborGen in September 2024 after more than five years as a Procurement Forester with increasing levels of responsibility for International Paper and Interfor. As a procurement forester, Blake was responsible for evaluating and pricing tracts, coordinating deliveries to mills, and managing inventory.

When selling your timber, there are a lot of factors that determine the price you will receive. How old is your timber? How many acres are you selling? What bid format will you choose? What does the wood look like? That last question is the most subjective, as “beauty is in the eye of the beholder.” What one may view as a beautiful stand of high-value logs, someone else may view as a tract of timber with too many issues to be worth offering a high price. My five years of experience in log procurement before joining ArborGen allows me to share with landowners how log quality can harm (or help) the final value of your product before and during a sale.

A tract’s stumpage value (the price the landowner gets paid for their trees) is determined when a buyer first inspects it. Typically, landowners have their timber evaluated by a wood dealer, logger, or mill without a formal timber cruise, considering wood quality, ground conditions, and accessibility. If the tract seems valuable, a timber cruise may be conducted. Some landowners opt to sell by ton based on product type instead. After initial observations, the logger or dealer assesses available markets, mill capacity, cut and haul rates, and stumpage prices to establish per-ton values for the stand’s products. Timber cruise volumes, which estimate product classes based on log size and quality, are then converted into prices per ton.

Once a logger starts cutting, the loader operator performs an eye test on each log, translating estimates from the forester’s timber cruise into loads for the market. They face conflicting incentives: maximizing production, sorting wood for value, and minimizing rejected loads. These goals can contradict each other; overall production slows if extra processing is needed to handle defective logs. Cull penalties, which reduce payment per ton for logs with quality issues, are often borne by the logger, even if they didn’t cause the defects. Both the landowner and logger face penalties when sending defective logs to the mill. To avoid culls, the loader operator might be incentivized to “play it safe,” downgrading trees to pulpwood, which has significantly lower value and can be challenging to sell.

Meanwhile, the landowner wants maximum effort in sorting and processing the logs to the highest value products, and the timber dealer wants to satisfy the landowner. They may have even bought the tract lump sum and need it to “cut out” to recuperate their investment. So, as a loader operator is working with all these constraints in the back of their head, they are sorting logs, one by one, hundreds per day, making value judgments from their machine’s cab. Estimating butt diameter, top diameter, acceptable sweep, depth of canker, number of knots, log length, and a multitude of other attributes while using the tools available (delimber, buck saw, sometimes a processing head) to optimize a solution for their logging crew, landowner, and mill. This is another chance for a stand’s value to change depending on the eye test.

Despite suppressed lumber markets, capital investments in sawmills continue to increase in the US South. As we continue to struggle with contracting pulpwood markets, it is imperative to consider how you want your next stand to look; will it pass the eye test? When planning your next stand, remember the practical implications of harvesting and processing a stand of high-defect trees. Always ask for a PRS sheet on the seedlings you are considering planting, and know that seedlings are being developed for tomorrow’s markets. You do not have to compromise for the genetics of yesteryear.

Blake Sherry will be featured on the next two episodes of the TreeLines Podcast, where he will discuss his expertise in Procurement Forestry in more detail. Contact your Reforestation Advisor for more information on planting the MCP® trees sawmills need.